BUILDING WATER ROCKET COMPONENTS

WITH A 3D PRINTER

To

succeed

with

the

construction

of

a

water

rocket,

you

will

have

to

work

very

precisely

and

carefully.

Especially

some

of

the

adhesives

are

pretty

dangerous.

Thus,

please

wear

gloves

when

working

with

adhesive

or

epoxy

and

don‘t

breathe

in

the

gases.

It

is

recommended

to

work

outside

whenever

toxic

gases

could

develop.

The

launch

of

a

water

rocket

may

needs

permission

from

the

competent

authority,

depending

on

your

location.

You

need

the

permission

of

the

landowner

if

you

launch

on

foreign

territory.

Please

wear

safety

goggles

when

pressure

testing

or

launching

your

rocket.

Keep

a

safe

distance

to

the

pressurized

rocket.

We

can

not

guarantee

the

accuracy,

completeness

or

feasibility

of

any

our

tutorials.

We

are

not

responsible

for

any

damage

or

harm

on

objects,

animals

or

humans.

We

do

not

guarantee

that

the

information

provided

on

this

web

site

is

complete,

accurate

and

always

current.

This

applies

also

to all links cited on this website points, either directly or indirectly. We are not responsible for any damage or harm to objects or individuals.

SAFETY GUIDELINES AND DISCLAIMER

DON‘T WORRY, THERE ARE 3D PRINTSHOPS.

In

the

last

few

years,

3D

Printers

have

become

an

incredibly

powerful

tool

to

create

components.

This

is

especially

true

for

Water

Rockets,

because

the

production

of

3D

printed

componnts

is

affordable,

and

they

are

light

and

water

resistant.

In

cooperation

with

DLR_School_Lab

we

offer

a

selection

of

blue

prints

and

3D

printing

files

which

you

can

download

and

modify. If you want to learn more about the cooperation with DLR_School_Lab, learn more

here.

YOU DON‘T HAVE A 3D PRINTER?

IT‘S YOUR CHOICE!

You

can

not

only

download

the

files

for

your

3D

printer,

but

you

can

also

download,

adjust

and

enhance

the

original

blue

prints.

In

order

to

do

this,

you

have

to

install

FreeCAD

,

which

is

free

for

Windows/Mac/Linux

users.

If

you

need

help

with FreeCAD, there are many tutorials available on the internet.

IN COOPERATION WITH DLR_SCHOOL_LAB

All

3D

components

offered

on

this

site

were

designed

and

tested

in

DLR_School_Lab

Lampoldshausen/Stuttgart

with

the

help

of

Raketfued

Rockets.

The

German

Aerospace

Center

(DLR)

is

one

of

Europe‘s

largest

and

most

modern

research

institutions

and

offers

children

and

young

people

an

opportunity

to

discover

for

themselves

the

fascinating

world

of

research.

After

filling

in

the

application

form,

students

and

classes

can

visit

the

School_Labs,

which

are

located

at

many

DLR sites in Germany, for free.

PodPad

Simple and safe Water Rocket Launcher

IMPORTANT NOTE:

The

launcher

has

to

be

tested

elaborately

before

its

first

use,

because

the

manufacturing

and

printing conditions can not be controlled and may vary from our 3D printed models.

Learn more

With optional thread

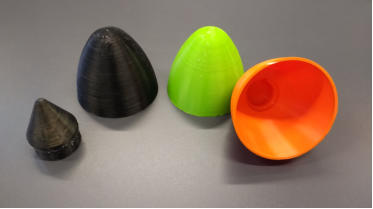

Nosecones

With different diameters.

Nozzles

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

to

seal

the

nozzles.

Before

its

first

use,

test

the

nozzles

elaborately. Manufacturing conditions can not be controlled and may vary.

Learn more

A safe recovery system.

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

and

test

the

recovery

system

elaborately

before

its

first

use. Manufacturing conditions can not be controlled and may vary.

Learn more

Phoenix 3D

CHECK AND TEST YOUR COMPONENTS!

Some

of

the

3D-printed

components

available

for

download

on

this

website

are

exposed

to

high

pressure

and

loads.

Although

we

offer

CAD

files

for

download,

we

cannot

quarantee

for

functionality

of

these

components,

as

there

are

many

factors

during

the

manufacturing

process

we

cannot

control.

For

this

reason,

it

is

absolutely

necessary

to

test

critical

components

in

a

safe

environment.

Parts

that

will

be

under

pressure(e.

g.

nozzles,

connectors

and

tornado

tubes)

should

be

tested

by

filling

a

test

rocket

completely

with

water

and

pressurizing

it

behind

a

barrier.

Mechanically

movable

components

such

as

those

found

in

the

parachute

system

and

the

launch

pad

should

also

be

thoroughly

tested

before

use.

PodPad

is

a

simple

3D

printed

launcher.

Just

pull

the

trigger

line

from

a

safe

distance

and

your

water

rocket

will

launch.

Besides

the

3D

printed

components

you

will

need

some

additional

materials like a garden hose, PVC pipes and a fitting coupling.

Many

of

our

previous

water

rockets

have

relied

on

fireworks

rocket

nosecones.

But

searching

for

those

nosecones

was

pretty

annoying.

With

the

capabilities

of

3D

printing

we

were

finally

able

to

print

perfectly

sized

nosecones.

Additionaly,

we

have

engineered

nosecones

which

can

be

srewed

onto

the

bottle

threads.

Water

rocket

nozzles

can

either

be

build

at

home,

bougt

or

produced

with

a

3D

printer.

3D

printed

nozzles

allow

you

to

customize

your

nozzle

opening

diameter

(from

4-10mm).

All

nozzles

are

compatible

with

most

standard

garden

hose

couplings.

Our

3D

printed

recovery

system

is

very

light

and

stable.

It

also

has

no

edges

on

the

inside

to

enable

a

safe

parachute

ejection.

There

are

versions

for

different

bottle

diameters

and

with

tommy

timer

or

servo

activation.

Learn

more

about

it

in

the

manual.

English

Change language:

Payload Fairing Mechanism

for transporting payloads like a CanSat or a mini Tesla

Our

Payload

Fairing

Mechanism

(PFM)

allows

you

to

release

a

payload

like

a

"real"

rocket

by

separating

two

payload

fairing

parts.

With

this

mechanism

we

made

our

Tesla

project

happen,

but it is also conceivable to transport a probe or CanSats.

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

and

test

the

mechanism

elaborately

before

its

first

use.

Manufacturing conditions can not be controlled and may vary.

Learn more

To

succeed

with

the

construction

of

a

water

rocket,

you

will

have

to

work

very

precisely

and

carefully.

Especially

some

of

the

adhesives

are

pretty

dangerous.

Thus,

please

wear

gloves

when

working

with

adhesive

or

epoxy

and

don‘t

breathe

in

the

gases.

It

is

recommended

to

work

outside

whenever

toxic

gases

could

develop.

The

launch

of

a

water

rocket

may

needs

permission

from

the

competent

authority,

depending

on

your

location.

You

need

the

permission

of

the

landowner

if

you

launch

on

foreign

territory.

Please

wear

safety

goggles

when

pressure

testing

or

launching

your

rocket.

Keep

a

safe

distance

to

the

pressurized

rocket.

We

can

not

guarantee

the

accuracy,

completeness

or

feasibility

of

any

our

tutorials.

We

are

not

responsible

for

any

damage

or

harm

on

objects,

animals

or

humans.

We

do

not

guarantee

that

the

information

provided

on

this

web

site

is

complete,

accurate

and

always

current.

This

applies

also

to

all

links

cited

on

this

website

points,

either

directly

or

indirectly.

We

are

not

responsible

for

any

damage

or

harm

to

objects

or

individuals.

SAFETY GUIDELINES AND DISCLAIMER

BUILDING WATER ROCKET COMPONENTS

WITH A 3D PRINTER

DON‘T WORRY, THERE ARE 3D PRINTSHOPS.

In

the

last

few

years,

3D

Printers

have

become

an

incredibly

powerful

tool

to

create

components.

This

is

especially

true

for

Water

Rockets,

because

the

production

of

3D

printed

componnts

is

affordable,

and

they

are

light

and

water

resistant.

In

cooperation

with

DLR_School_Lab

we

offer

a

selection

of

blue

prints

and

3D

printing

files

which

you

can

download

and

modify.

If

you

want

to

learn

more

about

the

cooperation

with

DLR_School_Lab,

learn more

here.

YOU DON‘T HAVE A 3D PRINTER?

IT‘S YOUR CHOICE!

You

can

not

only

download

the

files

for

your

3D

printer,

but

you

can

also

download,

adjust

and

enhance

the

original

blue

prints.

In

order

to

do

this,

you

have

to

install

FreeCAD

,

which

is

free

for

Windows/Mac/Linux

users.

If

you

need

help

with

FreeCAD,

there

are

many

tutorials

available

on

the

internet.

IN COOPERATION

WITH DLR_SCHOOL_LAB

All

3D

components

offered

on

this

site

were

designed

and

tested

in

DLR_School_Lab

Lampoldshausen/Stuttgart

with

the

help

of

Raketfued

Rockets.

The

German

Aerospace

Center

(DLR)

is

one

of

Europe‘s

largest

and

most

modern

research

institutions

and

offers

children

and

young

people

an

opportunity

to

discover

for

themselves

the

fascinating

world

of

research.

After

filling

in

the

application

form,

students

and

classes

can

visit

the

School_Labs,

which

are

located

at

many DLR sites in Germany, for free.

PodPad

Simple and safe Water Rocket Launcher

IMPORTANT NOTE:

The

launcher

has

to

be

tested

elaborately

before

its

first

use,

because

the

manufacturing

and

printing

conditions

can

not

be

controlled and may vary from our 3D printed models.

Learn more

With optional thread

Nosecones

With different diameters.

Nozzles

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

to

seal

the

nozzles.

Before

its

first

use,

test

the

nozzles

elaborately.

Manufacturing

conditions

can not be controlled and may vary.

Learn more

A safe recovery system.

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

and

test

the

recovery

system

elaborately

before

its

first

use.

Manufacturing

conditions

can

not

be

controlled and may vary.

Learn more

Phoenix 3D

CHECK AND TEST YOUR COMPONENTS!

Some

of

the

3D-printed

components

available

for

download

on

this

website

are

exposed

to

high

pressure

and

loads.

Although

we

offer

CAD

files

for

download,

we

cannot

quarantee

for

functionality

of

these

components,

as

there

are

many

factors

during

the

manufacturing

process

we

cannot

control.

For

this

reason,

it

is

absolutely

necessary

to

test

critical

components

in

a

safe

environment.

Parts

that

will

be

under

pressure(e.

g.

nozzles,

connectors

and

tornado

tubes)

should

be

tested

by

filling

a

test

rocket

completely

with

water

and

pressurizing

it

behind

a

barrier.

Mechanically

movable

components

such

as

those

found

in

the

parachute

system

and

the

launch

pad

should

also

be thoroughly tested before use.

PodPad

is

a

simple

3D

printed

launcher.

Just

pull

the

trigger

line

from

a

safe

distance

and

your

water

rocket

will

launch.

Besides

the

3D

printed

components

you

will

need

some

additional

materials

like

a

garden

hose,

PVC

pipes and a fitting coupling.

Many

of

our

previous

water

rockets

have

relied

on

fireworks

rocket

nosecones.

But

searching

for

those

nosecones

was

pretty

annoying.

With

the

capabilities

of

3D

printing

we

were

finally

able

to

print

perfectly

sized

nosecones.

Additionaly,

we

have

engineered

nosecones

which

can

be

srewed onto the bottle threads.

Water

rocket

nozzles

can

either

be

build

at

home,

bougt

or

produced

with

a

3D

printer.

3D

printed

nozzles

allow

you

to

customize

your

nozzle

opening

diameter

(from

4-

10mm).

All

nozzles

are

compatible

with

most

standard garden hose couplings.

Our

3D

printed

recovery

system

is

very

light

and

stable.

It

also

has

no

edges

on

the

inside

to

enable

a

safe

parachute

ejection.

There

are

versions

for

different

bottle

diameters

and

with

tommy

timer

or

servo

activation.

Learn

more about it in the manual.

Raketfued PFM

for transporting payloads

Our

Payload

Fairing

Mechanism

(PFM)

allows

you

to

release

a

payload

like

a

"real"

rocket

by

separating

two

payload

fairing

parts.

With

this

mechanism

we

made

our

Tesla

project

happen,

but

it

is

also

conceivable

to

transport

a probe or CanSats.

IMPORTANT NOTE:

Follow

the

instructions

in

the

manual

and

test

the

mechanism

elaborately

before

its

first

use.

Manufacturing

conditions

can

not

be

controlled and may vary.

Learn more

English

Change language:

HOME

ABOUT US

ROCKETS

LAUNCHES

ARTICLES

TUTORIALS

EDUCATION

HOME

ABOUT US

ROCKETS

LAUNCHES

ARTICLES

TUTORIALS

EDUCATION