English

Change language:

In

February

2018,

Space

X

launched

their

rocket

Falcon

Heavy

for

the

first

time

and

it‘s

now

the

biggest

rocket

in

operation.

But

besides

being

very

powerful

the

most

interesting

part

of

this

rocket

is

it‘s

reusability

-

the

first

stage

and

the

boosters

can

land

back

on

earth

using

their

engines.

To

test

this

new

rocket,

Space

X

decided

to

not

launch

a

satellite

but

a

Tesla

Roadster.

The

live

stream

of

the

launched

was

watched

by

millions

of

space

enthusiasts

around

the

world.

The

most

exciting

moment

was

-

besides

the

return

of

the

boosters

-

the

separation

of

the

fairings

(you

can

see

the

fairing

separation

in

the

video

at

1:02).

The

amazing

footage

of

the

Tesla

Roadster

in

front

of

the

earth

made

us

wonder

if

we

were

able

to

achieve

a

similar

moment

with

a

water

rocket.

And

so

we

decided

to

try

our

best

to

build

a

mechanism

which

would allow us to separate the fairing and to launch a mini Tesla.

THE INSPIRATION - FALCON HEAVY & STARMAN

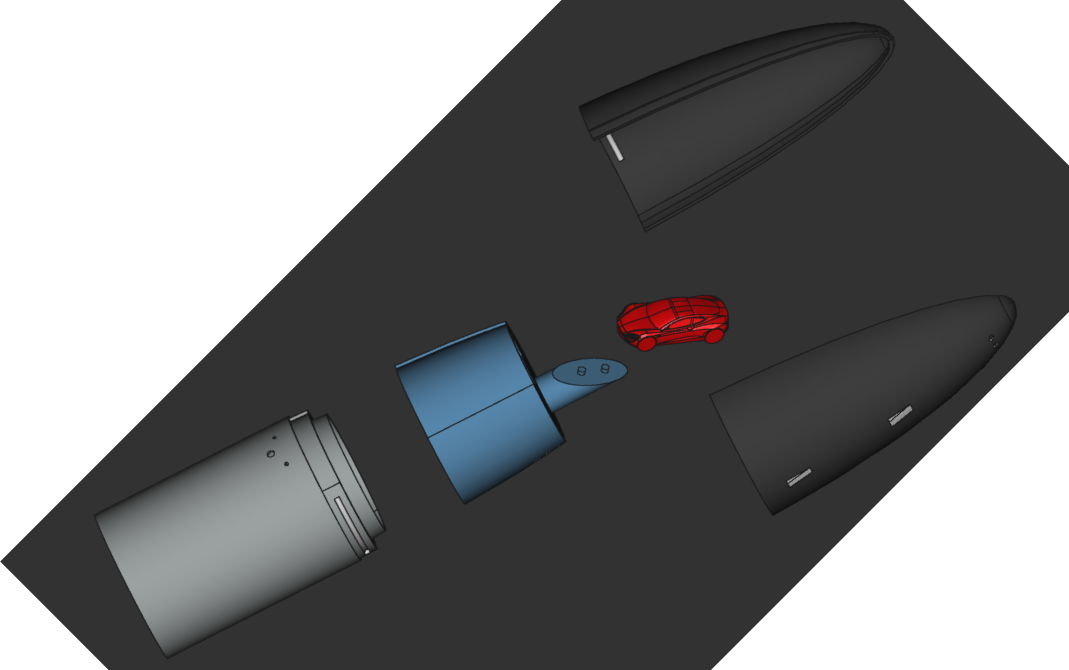

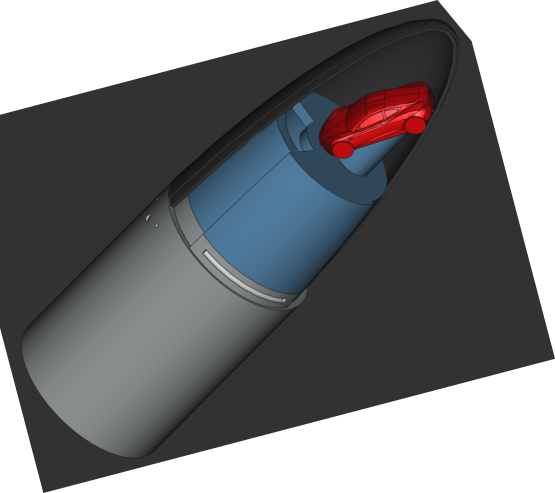

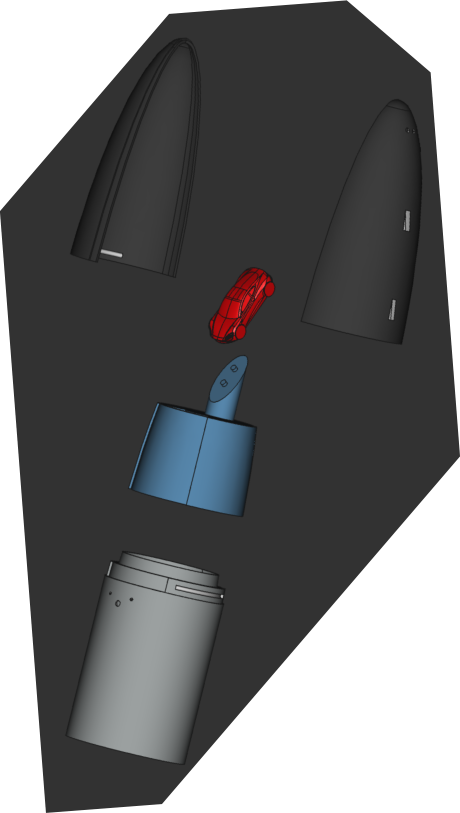

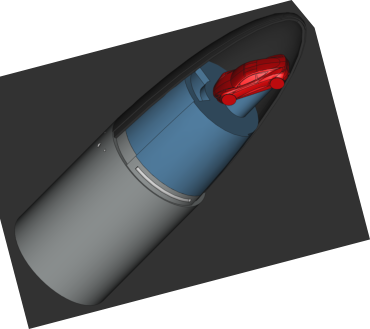

EARLY CONCEPTS

The

technical

most

challenging

part

of

the

project

was

to

make

a

fairing

which

would

act

the

same

way

the

fairing

on

Falcon

Heavy

and

most

other

rockets

does:

The

fairing

consists

of

two

parts

which

are

separated

and

fall

back

to

earth.

Thus, it should be possible to recreate the footage of the separation a with our mini tesla.

From

the

very

beginning

it

was

clear

that

the

mechanism

would

be

manufactured

using

3D

printing

because

this

project

is

difficult

to

realize

otherwise,

as

the

fairing

halves

have

to

fit

very

closely

together.

We

already

had

experience

in

developing

3D-printed

parachute

systems

at

that

time,

so

we

knew

roughly

what

to

do.

During

the

design

process

we

found

out

that

the

separation

of

the

fairing

can

be

combined

very

well

with

the

ejection

of

a

probe

or

a

CanSat.

With

the

Earth

Observation

Water

Rocket,

we

have

already

successfully

ejected

a

small

CanSat

in

2017,

which

collected

separated

from

the

rocket

various

environmental

data.

At

that

time,

however,

the

mechanism

was

vulnerable

and

required

a

lot

of

preparation

time

before

the

probe

could

be

started.

Our

experience

with

the

3D

printer

has

enabled

us

to

make

such

a

mechanism

much

safer,

more

flexible

and

easier.

So

we

decided

to

launch

our

mini-car

with

a

detachable

probe

-

this

means

that

the

Tesla

returns

separately

from

the

actual

rocket

on

the

parachute.

The

advantage

of

this

system

is

a

longer

flight

of

the

Tesla,

better

possibilities

for

the

camera

placement

at

the

rocket

and

of

course

that

our

newly

developed

system

can

also

be

used

for

other purposes than the launch of a toy car.

LAUNCHING A MINI TESLA

WITH OUR PAYLOAD FAIRING MECHANISM FOR WATER ROCKETS

19th June 2018

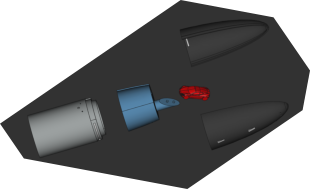

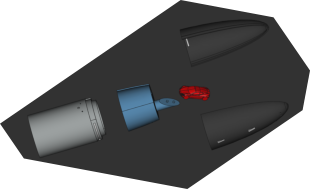

COMPONENTS

Rocket adapter

Probe with Tesla

Fairings

Is

mounted

on

the

rocket

and

holds

the

probe

and

the

fairings

in

position.

The

Tommy

Timer

or

Servo

is

attached

to

this part.

In

this

case,

the

probe

consists

of

the

Tesla

and

a

casing

for

the

parachute

and

an

onboard

camera.

The

fairings

are

hold

in

position

with

a

rubber

band,

which

is

wrapped

around

them.

There

are

little

hooks

on

the

outside

to

prevent

the

band from slipping.

FIRST FLIGHT ON 17TH JUNE 2018

Four

months

after

the

launch

of

the

Falcon

Heavy,

on

17th

June

2018,

we

were

finally

ready:

On

our

72nd

launch

day

we

launched

the

Payload

Fairing

Mechanism

together

with

the

Tesla

onboard

the

modified

Arrow

2

rocket.

This

modified

version

of

the

rocket

weighs

more

than

900g

at

launch,

as

it

has

two

onboard

cameras

in

addition

to

the

mechanism

and

two

parachutes.

Besides

slight

wind

heights,

the

location

of

the

launch

site

in

Lampoldshausen,

which

was

surrounded

by

high

corn

fields,

made

launch

conditions

difficult.

For

this

reason

we

decided

to

tie

the

Tesla

to

the

rocket

with

a

10m

long

cord so that it would not get lost together with the onboard camera.

We

launched

at

14

bar

/

200

psi

and

the

rocket

flew

straight

up,

where

the

fairing

mechanism

ejected

the

Tesla

as

planned. Both the rocket and the Tesla landed at a shorter distance than expected from the launch pad.

DOWNLOAD THE MECHANISM

If

you

would

like

to

launch

a

payload

yourself

using

a

water

rocket,

you

can

download

the

payload

fairing

mechanism

files

in our 3D printing area and adapt the mechanism to your own needs.

In

February

2018,

Space

X

launched

their

rocket

Falcon

Heavy

for

the

first

time

and

it‘s

now

the

biggest

rocket

in

operation.

But

besides

being

very

powerful

the

most

interesting

part

of

this

rocket

is

it‘s

reusability

-

the

first

stage

and

the

boosters

can

land

back

on

earth

using

their

engines.

To

test

this

new

rocket,

Space

X

decided

to

not

launch

a

satellite

but

a

Tesla

Roadster.

The

live

stream

of

the

launched

was

watched

by

millions

of

space

enthusiasts

around

the

world.

The

most

exciting

moment

was

-

besides

the

return

of

the

boosters

-

the

separation

of

the

fairings

(you

can

see

the

fairing

separation

in

the

video

at

1:02).

The

amazing

footage

of

the

Tesla

Roadster

in

front

of

the

earth

made

us

wonder

if

we

were

able

to

achieve

a

similar

moment

with

a

water

rocket.

And

so

we

decided

to

try

our

best

to

build

a

mechanism

which

would

allow

us

to

separate

the

fairing

and

to

launch a mini Tesla.

THE INSPIRATION

EARLY CONCEPTS

The

technical

most

challenging

part

of

the

project

was

to

make

a

fairing

which

would

act

the

same

way

the

fairing

on

Falcon

Heavy

and

most

other

rockets

does:

The

fairing

consists

of

two

parts

which

are

separated

and

fall

back

to

earth.

Thus,

it

should

be

possible

to

recreate

the

footage

of

the

separation a with our mini tesla.

From

the

very

beginning

it

was

clear

that

the

mechanism

would

be

manufactured

using

3D

printing

because

this

project

is

difficult

to

realize

otherwise,

as

the

fairing

halves

have

to

fit

very

closely

together.

We

already

had

experience

in

developing

3D-printed

parachute

systems

at

that

time,

so

we

knew

roughly

what

to

do.

During

the

design

process

we

found

out

that

the

separation

of

the

fairing

can

be

combined

very

well

with

the

ejection

of

a

probe

or

a

CanSat.

With

the

Earth

Observation

Water

Rocket,

we

have

already

successfully

ejected

a

small

CanSat

in

2017,

which

collected

separated

from

the

rocket

various

environmental data.

At

that

time,

however,

the

mechanism

was

vulnerable

and

required

a

lot

of

preparation

time

before

the

probe

could

be

started.

Our

experience

with

the

3D

printer

has

enabled

us

to

make

such

a

mechanism

much

safer,

more

flexible

and

easier.

So

we

decided

to

launch

our

mini-car

with

a

detachable

probe

-

this

means

that

the

Tesla

returns

separately

from

the

actual

rocket

on

the

parachute.

The

advantage

of

this

system

is

a

longer

flight

of

the

Tesla,

better

possibilities

for

the

camera

placement

at

the

rocket

and

of

course

that

our

newly

developed

system

can

also

be

used

for

other purposes than the launch of a toy car.

LAUNCHING A TESLA

WITH OUR PAYLOAD FAIRING MECHANISM

19th June 2018

COMPONENTS

Rocket adapter

Probe with Tesla

Fairings

Is

mounted

on

the

rocket

and

holds

the

probe

and

the

fairings

in

position.

The

Tommy

Timer

or

Servo

is

attached

to

this part.

In

this

case,

the

probe

consists

of

the

Tesla

and

a

casing

for

the

parachute

and

an

onboard

camera.

The

fairings

are

hold

in

position

with

a

rubber

band,

which

is

wrapped

around

them.

There

are

little

hooks

on

the

outside

to

prevent

the

band from slipping.

FIRST FLIGHT ON 17TH JUNE 2018

Four

months

after

the

launch

of

the

Falcon

Heavy,

on

17th

June

2018,

we

were

finally

ready:

On

our

72nd

launch

day

we

launched

the

Payload

Fairing

Mechanism

together

with

the

Tesla

onboard

the

modified

Arrow

2

rocket.

This

modified

version

of

the

rocket

weighs

more

than

900g

at

launch,

as

it

has

two

onboard

cameras

in

addition

to

the

mechanism

and

two

parachutes.

Besides

slight

wind

heights,

the

location

of

the

launch

site

in

Lampoldshausen,

which

was

surrounded

by

high

corn

fields,

made

launch

conditions

difficult.

For

this

reason

we

decided

to

tie

the

Tesla

to

the

rocket

with

a

10m

long

cord

so

that

it

would

not

get lost together with the onboard camera.

We

launched

at

14

bar

/

200

psi

and

the

rocket

flew

straight

up,

where

the

fairing

mechanism

ejected

the

Tesla

as

planned.

Both

the

rocket

and

the

Tesla

landed

at

a

shorter

distance

than

expected from the launch pad.

DOWNLOAD THE MECHANISM

If

you

would

like

to

launch

a

payload

yourself

using

a

water

rocket,

you

can

download

the

payload

fairing

mechanism

files

in

our

3D

printing

area

and

adapt the mechanism to your own needs.

English

Change language:

HOME

ABOUT US

ROCKETS

LAUNCHES

ARTICLES

TUTORIALS

EDUCATION

HOME

ABOUT US

ROCKETS

LAUNCHES

ARTICLES

TUTORIALS

EDUCATION